Bu-LOK is a specialised manufacturer of high quality ASME/ANSI/DIN industrial lap joint flanges in India. We offer immediate delivery programs for standard size carbon steel lap joint flanges and stainless steel lap joint flanges. Lap joint flanges manufactured in carbon steel, special stainless steel grades, nickel alloy and alloy steel can be supplied with just in time programs.

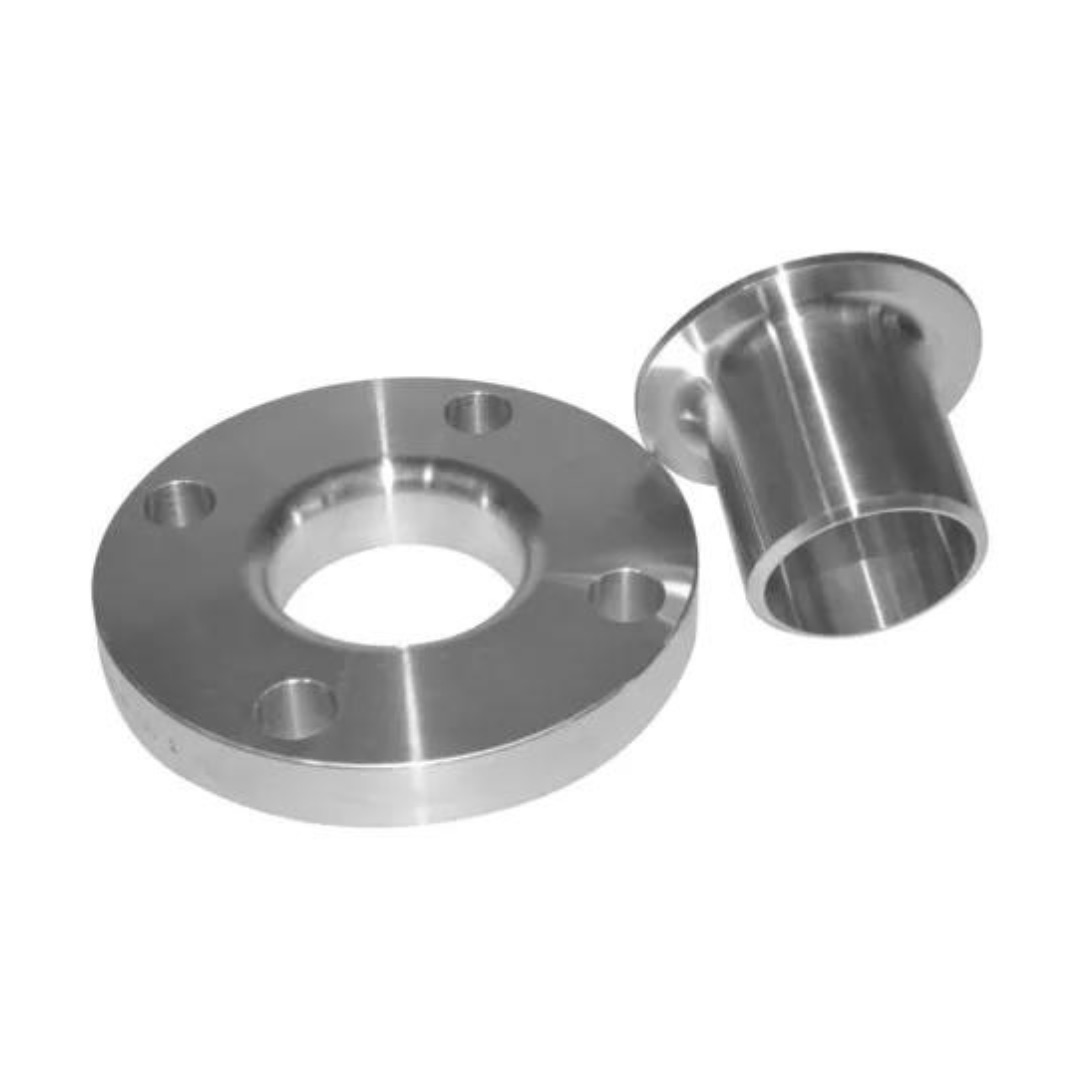

Lap Joint Flanges are similar to other types of industrial flanges, but it does not have a raised face. Lap joint flanges are used in conjunction with a “Lap Joint Stub End”. The total initial cost of a lap joint flange along with a stub end is around one-third higher than that of comparable welding neck flanges. The pressure holding capacity of lap joint flanges is comparatively lower, and the fatigue life for the assembly is only one tenth that of welding neck flanges.

The lap joint flange with the stub end assembly is normally used in piping systems which require regular dismantling for inspection and cleaning. These flanges slip over the pipe, and are not welded or otherwise fastened to it. Bolting pressure is transmitted to the gasket by the pressure of the flange against the back of the pipe lap (Stub End).

We offer lap joint flanges manufactured at our facility to companies in various industries including shipbuilding, power generation, petrochemical plants, oil refineries, waste water treatment plants, paper mills, pharmaceutical plants and turnkey projects among others.

Our products are widely exported to countries and regions such as the United States, Europe, Russia, Turkey, Malaysia, the UAE, Saudi Arabia, Iran, Brazil, Chile, Mexico, South Africa, Jordan, Tunisia, Vietnam, Indonesia, Thailand, Singapore, Colombia, and Sri Lanka.

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Standards | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Pressure Ratings | Class 150, Class 300, Class 400, Class 600, Class 900, Class1500, Class 2500 | PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Carbon Steel Lap Joint Flanges | ASTM A105/A105N, A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, A694 F42, F46, F48, F50, F52, F56, F60, F65, F70, A516.60, 65, 70 (Spectacle Blind Flange, Spacer Ring/Spade Flange), Steel RST37.2, C22.8 |

| Stainless Steel Lap Joint Flanges | ASTM A182 F202, F304/304L/304H, F316/316L, F316H, F316TI, F310, F321, F904L |

| Alloy Steel Lap Joint Flanges | ASTM A182 F1, F5, F9, F11, F22, F91 |

| Special Alloy Lap Joint Flanges | Duplex, Super Duplex, Nickel Alloys |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Coating/Surface Treatment | Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| Value Added Services | CNC Machining, Customised Flanges |

Products are packaged to ensure that there is no damage during transit. In case of exports, standard export packaging is done in wooden cases. All flanges are marked with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make custom marking on our products.

At Bllion Pipes, all fittings and flanges are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products.

Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report